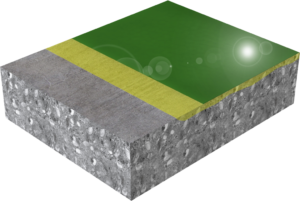

Chemical Containment Bunded

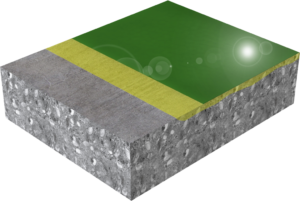

Secondary containment areas are designed to capture spills of oils, chemicals, or pollutants from primary containment tanks or vessels, helping to protect soil, vegetation, and groundwater from contamination.

There are two main requirements for protective coatings in contained bunds.

Waterproofing the bund is critical for the protection of the environment, it is essential contaminants are contained. Secondly is protecting the substrate from chemical attack which is aggressive to concrete and steel the core components of the structure.

CHARACTERISTICS:

Smooth, flexible, highly chemically resistant, glass fabric reinforced coating.

SPECIFICATIONS:

- Extreme chemical protection

- Very crack resistant

- Heavy duty fibreglass laminate

SIKA SYSTEM / PERFORMANCE:

Primer: SikaCor VEL

Seal coat: Laminate, SikaCor VEL, heavy duty fiberglass laminate

Total layer thickness: 2-3mm

Is a two part, self-smoothing, coloured epoxy resin with high chemical and mechanical resistance.

USES:

For concrete and screed surfaces in bund areas for protection against water contamination liquids.

CHARACTERISTICS:

High chemical resistance, high mechanical resistance, liquid proof, abrasion resistant and slip resistant surface possible.

SPECIFICATIONS:

- High wear and abrasion resistance

- High chemical resistance

- Waterproof

- Coloured

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/-161

Wearing course: Sikafloor-381, a two part, highly chemically resistant, coloured, epoxy binder for self-smoothing screeds.

Total layer thickness: ~2mm

Is a 2-pack total solid high build coating material based on epoxy resin.

USES:

For linings to storage tanks and silos, bund areas, wastewater tanks, geothermal cooling tower basins and reservoirs. Anti-corrosion coating in food processing plants, sewage works and farms and agricultural enterprises, chemical and pharmaceutical plants.

CHARACTERISTICS:

Solvent free, good chemical resistance, high build, impervious to liquids.

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

- Potable/drinkable water suitable

SIKA SYSTEM / PERFORMANCE:

Wearing course: Sikagard-62, a two part, high build, protective, epoxy coating for walls and floors.

Coating: Three coats, no primer necessary

Total layer thickness: 400-600 microns

CHARACTERISTICS:

Smooth, chemical resistant lining.

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

- Potable/drinkable water suitable

SIKA SYSTEM / PERFORMANCE:

Wearing course: Sikagard-62, a two part, high build, protective, epoxy coating for walls and floors.three coats, no primer necessary

Total layer thickness: 400-600 microns