Chemical Processing

These plants can damage unprotected concrete floors, making them vulnerable to chemical attack and corrosion.

It is important you understand what chemicals are involved within your processing plant and the potential hazards they create.

NZ Specialised Coatings can work with you and get an understanding of your processes, provide a flooring solution that will meet your requirements and can assist in a programmed maintenance plan.

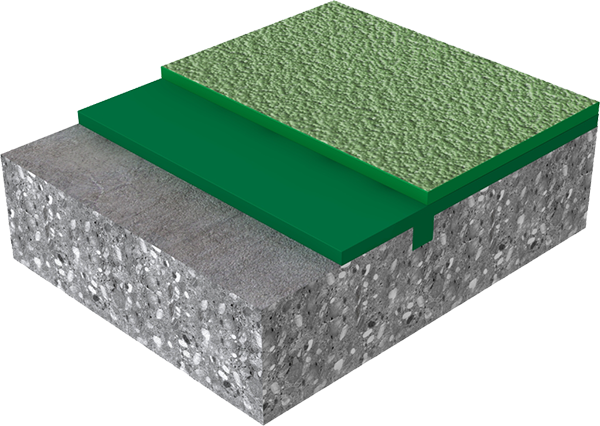

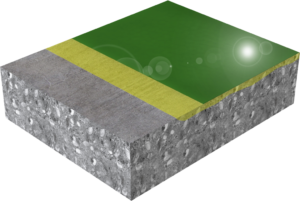

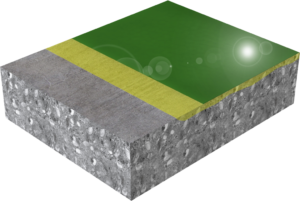

Is a four part, resin rich, water dispersed, high strength, trowel grade, coloured polyurethane modified, cement and aggregate screed suitable for floors subject to heavy loading, abrasion and chemical exposure?

USES:

Food processing plants, wet or dry areas, freezers and coolers, thermal shock areas. Chemical plants, laboratories, workshops.

CHARACTERISTICS:

Excellent chemical resistance, slip resistance, non-taint odourless, high abrasion resistance resulting from its silica aggregate structure. 6-9mm thick when laid. Fast curing and easily maintained.

SPECIFICATIONS:

- High wear resistance

- High chemical resistance

- High thermal shock resistance

- Slip resistant

- Odour-free

- Hygienic

- Coloured

- Easy to clean (including steam cleaning)

SIKA SYSTEM / PERFORMANCE:

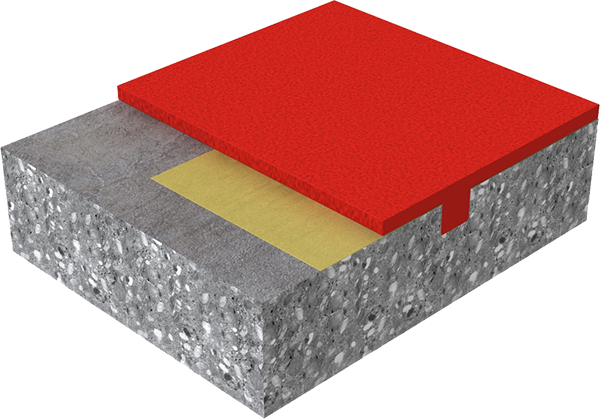

Primer: Generally not required. If necessary, use Sikafloor-156/-161 broadcast with quartz sand.

Screed: Sikafloor-20 PurCem, three / four part, easy trowel, polyurethane modified, cement based floor screed.

Total layer thickness: 6–9mm

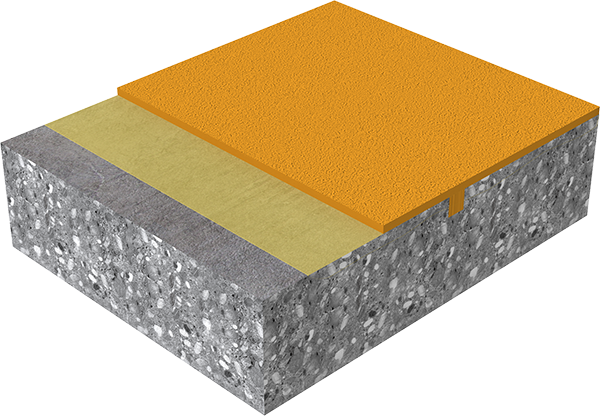

Is a three part, water dispersed medium to high strength coloured polyurethane modified, cement and aggregate screed with self-smoothing properties.

USES:

Food processing plants, in wet and dry process areas, freezers and coolers, thermal shock areas. Chemical plants, Laboratories and Workshops.

CHARACTERISTICS:

Excellent chemical resistance. Non taint, low odour. High abrasion resistance resulting from its silica aggregate structure. Joint less and easily maintained.

NON-SLIP SPECIFICATIONS:

- High wear resistance

- High chemical resistance

- Enhanced slip resistance

- High thermal shock resistance

- Hygienic

- Coloured

- Slip resistant

- Odour-free

SIKA SYSTEM / PERFORMANCE:

Primer: Generally not required

Base layer: Sikafloor-21 PurCem, three / four part, polyurethane modified, cement based screed.

Broadcast: Coloured or natural quartz sand (for enhanced slip resistance).

Seal coat: 1 – 2 x Sikafloor-31 PurCem, three part, water dispersed, polyurethane sealer coat.

Total layer thickness: 4.5–6mm

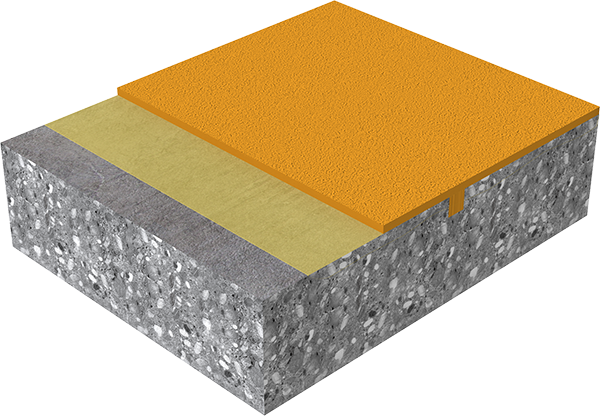

SMOOTH SPECIFICATIONS:

- High wear resistance

- High chemical resistance

- High thermal shock resistance

- Odour-free

- Hygienic

- Easy to clean

- Coloured

SIKA SYSTEM / PERFORMANCE:

Primer: Scratch coat Sikafloor-21 PurCem

Screed: Sikafloor-21 PurCem, hree / four part, self-smoothing, polyurethane modified, cement based screed.

Total layer thickness: 4.5–6mm

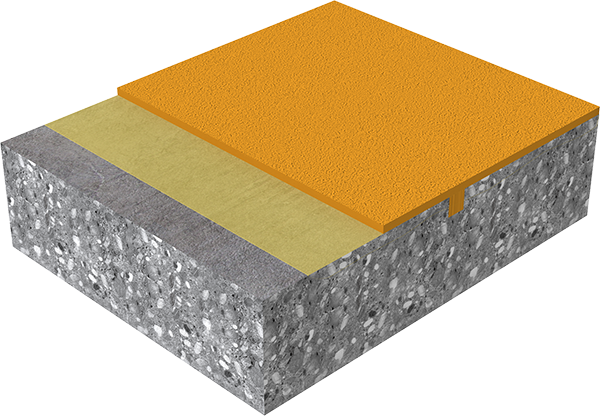

CHARACTERISTICS:

Medium to heavy duty, smooth screed.

SPECIFICATIONS:

- High wear resistance

- High chemical resistance

- High thermal shock resistance

- Odour-free

- Hygienic

- Easy to clean

- Coloured

SIKA SYSTEM / PERFORMANCE:

Primer: Scratch coat Sikafloor-21 PUrCem

Screed: Sikafloor-21 PurCem, three / four part, self-smoothing, polyurethane modified, cement based screed.

Total layer thickness: 4.5–6mm

Is a three part, solvent free, high build, coloured, matt finish, polyurethane modified, cement and aggregate coating with excellent chemical resistance and very good resistance to abrasion and mechanical damage.

USES:

Food processing plants in wet and dry process areas, freezers and coolers. Pharmaceutical plants, containment areas and Chemical process areas.

CHARACTERISTICS:

Excellent chemical resistance. Non taint, odourless, excellent long term wear resistance from a two coat application

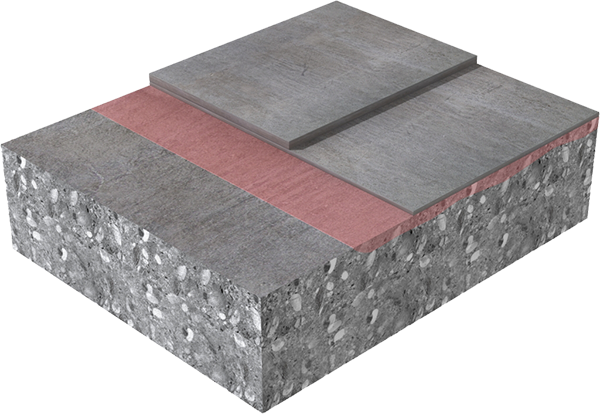

A three component solvent free, epoxy resin based patching mortar and screed for industrial floors subject to heavy traffic. A trowel finished screed applied in layers between 5-40mm thick.

USES:

Dairy manufacturing and processing plants, pulp and paper industry, Garages and engineering workshops, Warehouses, loading bays, ramps. Food preparation areas and Chemical processing areas.

CHARACTERISTICS:

Solvent free, non-tainting. Excellent resistance to abrasion, range of colours, impermeable to liquids, Good chemical resistance, high impact resistance and excellent adhesion.

SPECIFICATIONS:

- High wear resistance

- High chemical resistance

- Medium thermal shock resistance

- Slip resistant

- Odour-free

- Hygienic

- Easy to clean

- Coloured

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/-161

Screed: Sikafloor-91 or -156, epoxy screed

Total layer thickness: 5–6mm

Is a two part, self-smoothing, coloured epoxy resin with high chemical and mechanical resistance.

USES:

For concrete and screed surfaces in bund areas for protection against water contamination liquids.

CHARACTERISTICS:

High chemical resistance, high mechanical resistance, liquid proof, abrasion resistant and slip resistant surface possible.

SPECIFICATIONS:

- High wear and abrasion resistance

- High chemical resistance

- Waterproof

- Coloured

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/-161

Wearing course: Sikafloor-381, a two part, highly chemically resistant, coloured, epoxy binder for self-smoothing screeds.

Total layer thickness: ~2mm

CHARACTERISTICS:

Self-smoothing, temporary moisture barrier on “green” damp concrete.

SPECIFICATIONS:

- For concrete floors with damaged or missing DPC membrane

- No waiting time on “green” or damp concrete

- No blistering in the finish when coating damp concrete

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-155 WN

Base coat: Sikafloor-81 EpoCem, three part epoxy modified, cement based, self-smoothing screeds

Topping: Sikafloor resin system to suit

Total layer thickness: 2-3mm

SPECIFICATIONS:

- For surface damaged cementitious floors

- Reduced waiting time to overcoat green concrete

- No blisters on topping when coating damp concrete

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-155 WN

Screed: Sikafloor-81 EpoCem,

three component epoxy modified cementitious, self-smoothing screeds.

Topping: Sikafloor resin to suit

Total layer thickness: 2-3mm

Is a 2-pack total solid high build coating material based on epoxy resin.

USES:

For linings to storage tanks and silos, bund areas, wastewater tanks, geothermal cooling tower basins and reservoirs. Anti-corrosion coating in food processing plants, sewage works and farms and agricultural enterprises, chemical and pharmaceutical plants.

CHARACTERISTICS:

Solvent free, good chemical resistance, high build, impervious to liquids.

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

- Potable/drinkable water suitable

SIKA SYSTEM / PERFORMANCE:

Wearing course: Sikagard-62, a two part, high build, protective, epoxy coating for walls and floors.

Coating: Three coats, no primer necessary

Total layer thickness: 400-600 microns

CHARACTERISTICS:

Smooth, chemical resistant lining.

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

- Potable/drinkable water suitable

SIKA SYSTEM / PERFORMANCE:

Wearing course: Sikagard-62, a two part, high build, protective, epoxy coating for walls and floors.three coats, no primer necessary

Total layer thickness: 400-600 microns

CHARACTERISTICS:

Smooth, flexible, highly chemically resistant, glass fabric reinforced coating.

SPECIFICATIONS:

- Extreme chemical protection

- Very crack resistant

- Heavy duty fibreglass laminate

SIKA SYSTEM / PERFORMANCE:

Primer: SikaCor VEL

Seal coat: Laminate, SikaCor VEL, heavy duty fiberglass laminate

Total layer thickness: 2-3mm