Hard-wearing, durable and easy to clean floors are required for a service bay.

This could offer long-term performance and meet the daily demands of a busy service pit area. Excellent abrasion and impact resistance are a necessity for the daily rigours of a workshop floor.

Floor colour and safety are also form a vital role in the selection of your floor coating. The floor will have public access areas that will have to comply with the right degree of slip resistance as to meet required Health and Safety regulations.

NZ Specialised Coatings can apply a range of product colours to meet your flooring requirements.

PRODUCTS

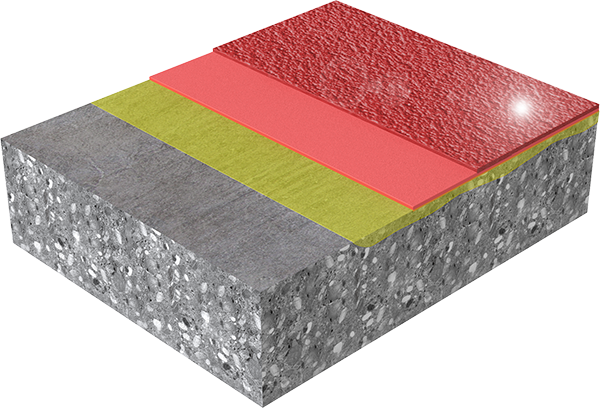

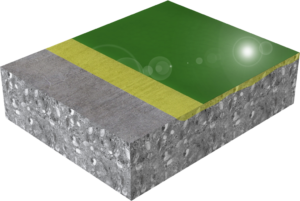

Sikafloor 264 Broadcast - Rigid Screed 1-3mm

CHARACTERISTICS:

Broadcast, coloured, rigid screed 1-3 mm

SPECIFICATIONS:

- High abrasion resistance

- Waterproof

- Slip resistance

- Aesthetics

- German standard (OS-8)

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/-161 (optional)

Base coat: Sikafloor-264, a solvent free, coloured epoxy binder, broadcast with Quartz sand.

Seal coat: Sikafloor-264

Total layer thickness: 1-3mm

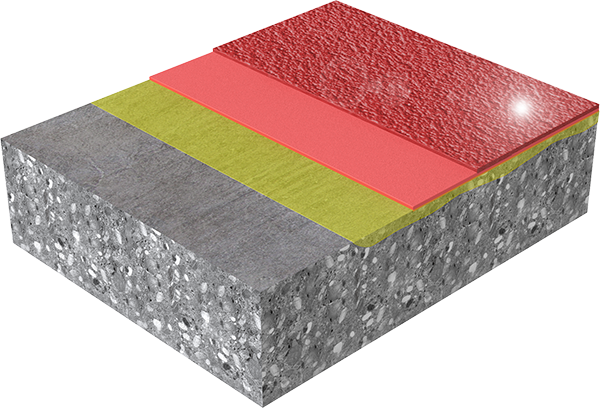

Sikafloor 264 Broadcast - Rigid Screed 2-4mm

CHARACTERISTICS:

Broadcast, coloured, rigid screed 2-4mm

SPECIFICATIONS:

- High wear resistance

- Good chemical resistance

- Medium thermal shock resistance

- Slip resistance

- Coloured

SIKA SYSTEM / PERFORMANCE:

Sika System / Performance

Primer: Sikafloor-156

Base coat: Sikafloor-264 NS, a two part, total solid, coloured, epoxy binder for textured broadcast systems.

Broadcast with Quartz sand.

Seal coat: Sikafloor-264

Total layer thickness: 2-4mm

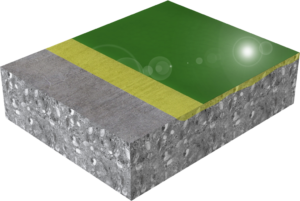

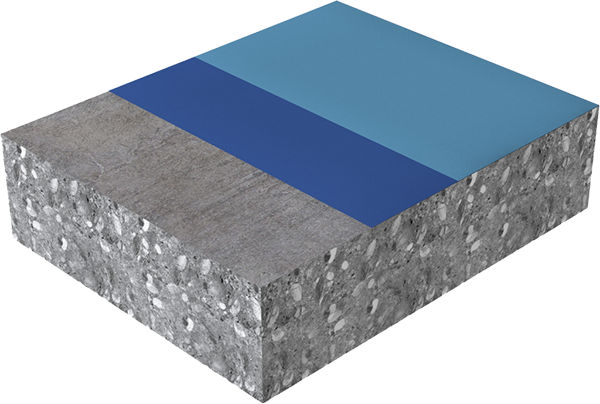

Sikafloor 264 Decorative - Roll On Coating

CHARACTERISTICS:

Decorative roll-on coating.

SPECIFICATIONS:

- Wear resistance

- Easy cleaning

- Decorative

SIKA SYSTEM / PERFORMANCE:

2 x Sikafloor-264, a two part, coloured, high build epoxy resin basedcoating.

Seal coat: Sikafloor-305, a water dispersed, coloured polyurethane based matt sealer.

Total layer thickness: 600-800 microns.

Sikafloor 264 Roll On

A 2-Part, economic, solvent-free coloured epoxy resin.

USES:

Roller coat for concrete and cement screeds with normal up to medium heavy wear e.g. storage an assemble halls, maintenance workshops, garages, loading ramps. Seal coat for broadcast systems, such as multi-story and undercover care parks, maintenance hangers and for wet process areas e.g. beverage and food industry, warehouse, vehicle showroom, dry areas, hangers and laboratories.

CHARACTERISTICS:

Good chemical and mechanical resistance, economical, solvent free, gloss finish and slip resistant surface possible.

SPECIFICATIONS:

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/ -161

Coating: Sikafloor-264, a two part, total solid, coloured, epoxy binder.

Total layer thickness: 600 – 800 microns

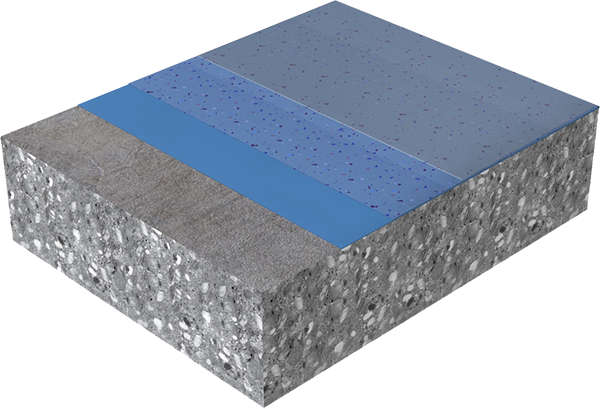

Sikafloor 264 Self Leveling

Is a thisotropice 2-component solvent free pigmented 100% solids high build epoxy coating for heavy duty and decorative finishes for walls and coves in addition to providing a textured floor coating.

USES:

Food processing industry, plastics industry, laboratories, aircraft hangers and workshops, washrooms, cloakrooms, chemical/pharmaceutical industries.

CHARACTERISTICS:

High mechanical properties, good abrasion resistance, high durability, coloured, joint less, easily cleaned and maintained, waterproof.

SPECIFICATIONS:

- High wear and abrasion resistance

- Good impact resistance

- Good chemical resistance

- Medium thermal resistance

- Easy cleaning

- Coloured

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-156/-161

Coating: Sikafloor-264 SL, a two part, coloured epoxy binder for self-smoothing screed systems.

Total layer thickness: 1-3mm

Sikafloor 264T

Is a thixotropic 2-component solvent free pigmented 100% solids high build epoxy coating for heavy duty and decorative finishes for walls and coves in addition to providing a textured floor coating.

USES:

Food processing industry, plastics industry, laboratories, aircraft hangers and workshops, washrooms, cloakrooms, chemical/pharmaceutical industries.

CHARACTERISTICS:

High mechanical properties, good abrasion resistance, high durability, coloured, joint less, easily cleaned and maintained.

Sikafloor 2540W

Two part, water dispersed, solvent free, coloured, epoxy resin based coating.

USES:

Coloured epoxy coating for concrete, cement screeds, broadcast systems and epoxy mortars. Workshops, warehouses, garages, walk ways.

CHARACTERISTICS:

Good chemical and mechanical resistance, water vapour permeable, water dilutable, odourless and easy application.

- Medium wear resistance

- Surface stabilization

- Prevent concrete dusting

- Coloured

- Low odour

SIKA SYSTEM / PERFORMANCE:

Coating: 2 x Sikafloor-2540 W, a two part, water dispersed, coloured, epoxy resin based coating.

Total layer thickness: 150-250 microns

Sikafloor Duraseal W

Is a clear two-component, water dispersed epoxy resin.

USES:

As a clear sealer for concrete floors that are subjected to light wear and abrasion. Workshops, warehouses, garages, walk ways, walls.

CHARACTERISTICS:

Reduces dusting, low odour, economical and reduces permeability.

SPECIFICATIONS:

- Prevent dusting

- Seal concrete surface

- Very low VOC

SIKA SYSTEM / PERFORMANCE:

Sikafloor Duroseal W, a 2-part, water based epoxy.

Sikafloor 24 Curehard or Purigo 5S

CHARACTERISTICS:

Clear surface harder for concrete.

SPECIFICATIONS:

- Economic surface hardening

- Good abrasion resistance

- Prevent surface dusting

- Curing to ASTM C-156

SIKA SYSTEM / PERFORMANCE:

1 – 2 x Sikafloor Curehard-24, a sodium silicate based liquid hardener sprayed and brushed into the substrate

OR

1 – 2 x Purigo 5S, a sodium silicate based liquid hardener sprayed and brushed into the substrate.

Sikaglaze PU – Gloss and Matt Versions

Is one component, non-yellowing, aliphatic, moisture curing, and polyurethane gloss coating containing UV light absorbers.

USES:

Ideal for interior and exterior seamless floors, concrete sealer and suitable as an aggregate glaze for embedding nonslip aggregates.

CHARACTERISTICS:

Flexible and heat resistant, one component moisture curing, clear, non-yellowing, high gloss and matt finish option, tough, hard wearing, Good chemical resistance and excellent abrasion resistance. Ideal for Warehouse, exposed concrete and vehicle showrooms.

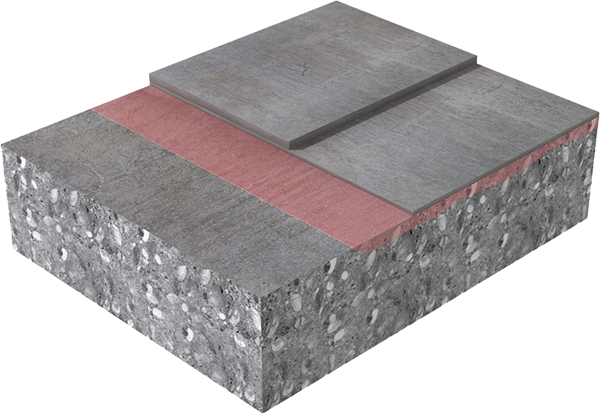

Sikafloor 81 EpoCem & 155WN SF

CHARACTERISTICS:

Self-smoothing, temporary moisture barrier on “green” damp concrete.

SPECIFICATIONS:

- For concrete floors with damaged or missing DPC membrane

- No waiting time on “green” or damp concrete

- No blistering in the finish when coating damp concrete

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-155 WN

Base coat: Sikafloor-81 EpoCem, three part epoxy modified, cement based, self-smoothing screeds

Topping: Sikafloor resin system to suit

Total layer thicnkess: 2-3mm

Sikafloor 81 EpoCem & 155WN

SPECIFICATIONS:

- For surface damaged cementitious floors

- Reduced waiting time to overcoat green concrete

- No blisters on topping when coating damp concrete

SIKA SYSTEM / PERFORMANCE:

Primer: Sikafloor-155 WN

Screed: Sikafloor-81 EpoCem,

three component epoxy modified cementitious, self-smoothing screeds.

Topping: Sikafloor resin to suit

Total layer thickness: 2-3mm